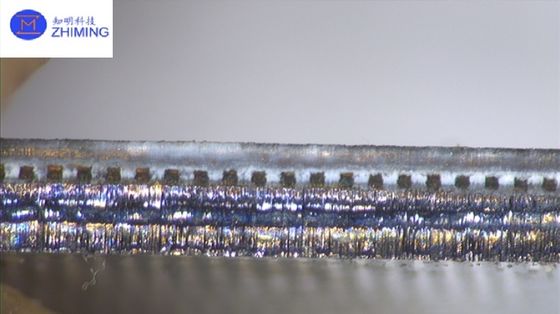

Sistema di separazione laser del substrato SiC da 6 a 12 pollici Wafer per macchine personalizzate

Il sistema Laser Lift-Off (LLO) è una tecnologia avanzata di elaborazione di precisione che utilizza laser pulsati ad alta energia per ottenere la separazione selettiva dei materiali alle interfacce.Questa tecnologia è ampiamente applicata nella produzione di semiconduttoriI suoi principali vantaggi includono l'elaborazione senza contatto, il controllo ad alta risoluzione e la compatibilità multi-materiale.rendendolo indispensabile per applicazioni quali il trasferimento di massa MicroLED, la fabbricazione di display flessibili e il confezionamento a livello di wafer semiconduttori.

I punti salienti del servizio aziendale:

Soluzioni personalizzate: lunghezza d'onda laser su misura (193 nm ∼1064 nm), potenza (1W ∼100 W) e integrazione di automazione per supportare la ricerca e lo sviluppo e la produzione di massa.

Sviluppo dei processi: ottimizzazione dei parametri laser, progettazione della modellazione del fascio e servizi di convalida (ad esempio, laser UV LLO per substrati di zaffiro).

Smart Maintenance: monitoraggio remoto integrato e diagnosi dei guasti, che garantisce un supporto operativo 24 ore su 24, 7 giorni su 7 con tempo di risposta < 2 ore.

Macchine per il sistema di separazione laserdi tparametri tecnici

| Parametro |

Valori tipici |

Nota. |

| Tipo laser |

Excimer (193nm/248nm), Femtosecondo (343nm/1030nm) |

Larghezza dell'impulso 5 ̊20ns, potenza massima > 10 kW |

| Area di lavorazione |

Max 150 mm × 150 mm |

Processo parallelo multi-stazione |

| Velocità di trattamento |

50 ∼ 300 mm/s |

Regolabile per materiale e potenza laser |

| Spessore di sollevamento |

10 nm ≈ 20 μm |

Capacità di delaminazione strato per strato |

| Integrazione dei sistemi |

Unità di pulizia EFU, sistema di trattamento dei gas di scarico |

conformità alla norma ISO 14644 in materia di pulizia |

Macchine per il sistema di separazione laserdi principio di funzionamento

L'LLO opera mediante ablazione selettiva alle interfacce del materiale:

Irradiazione laser: gli impulsi ad alta energia (ad esempio, laser excimer o femtosecondi) si concentrano sull'interfaccia bersaglio (ad esempio, zaffiro-GaN), inducendo reazioni fototermiche/fotochimiche.

Decomposizione dell'interfaccia: l'energia laser innesca la gasificazione (ad esempio, GaN → Ga + N2), generando plasma e tensione termica per la delaminazione controllata.

Raccolta dei materiali: le microstrutture delaminate vengono catturate mediante aspirazione a vuoto o dinamica dei fluidi, garantendo un trasferimento senza contaminazione.

Tecnologie chiave:

- Laser ultraveloci: gli impulsi di cinque secondi (< 100 f) riducono al minimo i danni termici (ad esempio, separazione MicroLED).

- Formazione del fascio: i profili lineari/ rettangolari del fascio aumentano l'efficienza (ad esempio, lavorazione flessibile dei lotti di PCB).

Caratteristiche del sistema

| - Sì.Caratteristica |

Specifiche tecniche |

Applicazioni |

| Processo senza contatto |

Energia laser trasmessa tramite l'ottica, evitando lo stress meccanico sui materiali fragili |

OLED flessibile, MEMS |

| Alta precisione. |

Accuratezza di posizionamento ±0,02 mm, controllo della densità energetica ±1% |

Trasferimento microLED, modellazione sub-μm |

| Compatibilità multi-materiale |

Supporta laser UV (CO2), visibili (verde) e IR; compatibile con metalli, ceramiche, polimeri |

Semiconduttori, dispositivi medici, energie rinnovabili |

| Controllo intelligente. |

Visione artificiale integrata, ottimizzazione dei parametri basata sull'IA, carico/scarico automatizzato |

Miglioramento dell'efficienza della produzione del 30%+ |

- Sì.

Macchine per il sistema di separazione laserdicampi di applicazione

1. fabbricazione di semiconduttori

- Imballaggio a livello di wafer: disconnessione laser per la separazione del chip su wafer, migliorando il rendimento.

- Sì.

- MicroLED/Microdisplay: trasferimento di massa di LED a scala μm su substrati di vetro/PET.

2- Elettronica flessibile

- Display pieghevoli: Delaminazione di circuiti flessibili da substrati di vetro (ad esempio, Samsung Galaxy Fold).

- Sì.

- Fabbricazione di sensori: stripping di precisione di ceramiche piezoelettriche per sensori tattili.

3. Dispositivi medici

- Trattamento con catetere: rimozione laser degli strati di isolamento per i condotti biocompatibili.

- Sì.

- Fabricazione di impianti: rimozione del rivestimento in lega di titanio per impianti ortopedici.

4. le energie rinnovabili

- Celle solari di perovskite: rimozione degli elettrodi conduttori trasparenti per ottimizzare l'efficienza.

- Sì.

- Moduli fotovoltaici: scribing laser per ridurre del 20% i rifiuti di wafer di silicio

Sistema di separazione laser macchina di FAQ

1D: Cos'è un sistema di sollevamento laser?

R: un sistema di sollevamento laser è uno strumento di elaborazione di precisione che utilizza laser pulsati ad alta energia per separare selettivamente i materiali alle interfacce,che consentono applicazioni come il trasferimento di massa MicroLED e la produzione flessibile di elettronica .

2. D: Quali industrie utilizzano i sistemi LLO?

R: I sistemi LLO sono fondamentali nella produzione di semiconduttori (imballaggi a livello di wafer), elettronica flessibile (display pieghevoli), dispositivi medici (fabbricazione di sensori),e rinnovabili (cellule solari), che offre elaborazione senza contatto e ad alta risoluzione.

Tags: #6-12 Inch, #1064nm, # SiC Substrate Laser Separation System Machine, #Wafers Customized

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!